Riverina Stockfeeds

Generating real-time equipment insights across remotely located factories through a combined dashboard

Key Points

- Riverina needed a system to improve operational reliability and efficiency with which equipment breakdowns and outages could be addressed

The system needed to:

1. Automatically collect data from existing factory equipment

2. Identify the data points required for effective performance monitoring

3. Structure and interpret collected data into clear, insightful visualisations

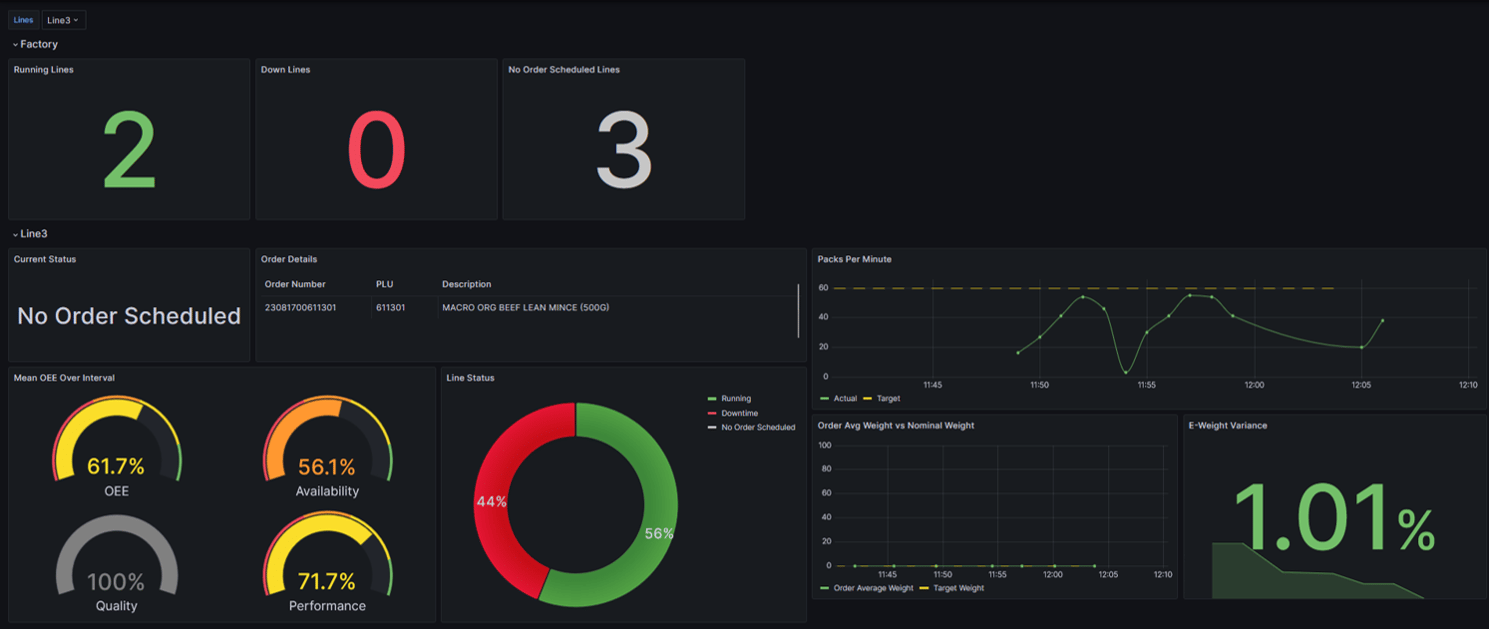

- Clevvi leveraged IoT SiteWise to transmit and visualise real-time data in a dashboard

- This cost-effective solution successfully unlocked a host of data insights for Riverina with minimal ongoing management

Riverina Australia is a leading manufacturer and supplier of stock feeds and supplements in Australia. Founded in 1927 and headquartered in Brisbane, the company has 8 branches across Queensland, New South Wales, and Western Australia. With almost 100 years of experience in animal feed production and commodity trading, Riverina has established strong connections in rural communities across Australia. With a complex network of factories spread across the country, Riverina aspired to take equipment monitoring capabilities to the next level by enhancing real-time insights.

Riverina faced several key challenges. They needed a solution that could collect data from existing equipment at their multiple remote factory locations and send it to the cloud for central monitoring and analysis. The data then had to be structured and translated into clear visualisations that provided insights into equipment effectiveness. Specific key data points needed to be identified to enable remote monitoring of equipment performance. Additionally, the solution had to be cost-efficient in terms of ongoing operation and maintenance.

To address these challenges, Riverina partnered with Clevvi and AWS to implement an IoT-based factory monitoring system. Clevvi connected the equipment at Riverina's 8 plants to AWS IoT SiteWise so that real-time operational data could be transmitted to the cloud. AWS IoT SiteWise dashboards were leveraged to visualise the factory data and provide valuable insights into equipment performance. Clevvi identified the most important data points to track overall equipment effectiveness and rapidly detect any issues. This enabled real-time remote monitoring capabilities across Riverina's entire fleet of plants.

The solution delivered significant results for Riverina Stockfeeds. The company gained real-time visibility into equipment performance across all feed processing plants. Dashboards provided data-driven insights to improve reliability and efficiency versus relying on gut feel. Issues like equipment breakdowns and outages could be addressed much faster. Enhanced preventative maintenance capabilities were unlocked. Importantly, the Clevvi solution provided all of this through a cost-efficient system requiring minimal ongoing management. By leveraging IoT and cloud technologies, Clevvi helped Riverina realise the benefits of actionable, real-time insights into factory operations across their multiple sites.

Trusted by 200+ Australia/New Zealand Customers

Australian Food and Fibre

AgricultureClevvi accessed real time ERP system data and overlaid this information on a device camera feed to a phone or tablet. The solution uses AR which shows product, weight and expiry in tubs using unique QR “license plates” instantly visually highlights expired product. The technologies included QR codes, computer vision/AR, Bluetooth/UWB, and data integration.

YouFoodz

Food Production

Transforming a complex, Excel-based model into a user-friendly web and mobile application that can cater to a userbase with wide-ranging computer literacy and allows continuous updates and easy maintenance by SRA staff.

Sugar Research Australia

AgricultureThe challenge to collect data from existing factory equipment, send to the cloud and also to structure and interpret the collected data to provide an easy-to-read, insightful and actionable visualisation, and identify the correct data points to enable remote equipment performance monitoring and cost-efficient to run and maintain.