Youfoodz

Rapid innovation and implementation of a custom augmented reality (AR) inventory management system for a global hackathon

Key Points

- Youfoodz needed an innovative solution to replace their manual inventory system due to inefficiencies and frequent errors

- Clevvi was invited to partake in a 2-day hackathon and designed a custom AR inventory management system that was estimated to reduce wastage by >10% and generate $500,000 in net annual savings for Youfoodz

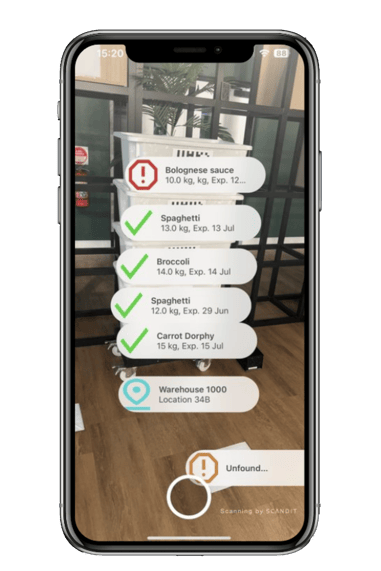

- Through rapid integration of real-time data, Clevvi developed an AR overlay for mobile camera feeds that provided the user with key details about the product they were scanning e.g. expiry

- The fully integrated solution seamlessly interfaced with Youfoodz's existing ERP and minimised inventory costs/errors

Youfoodz is a well renowned fresh meal preparation company owned by German multinational Hellofresh. As part of Hellofresh's broader innovation strategy, Youfoodz participates in the organisation's annual global hackathon events. These intensive 2-day hackathons facilitate collaboration between business units and technology partners to rapidly develop and prototype solutions that optimise operations and processes across the enterprise.

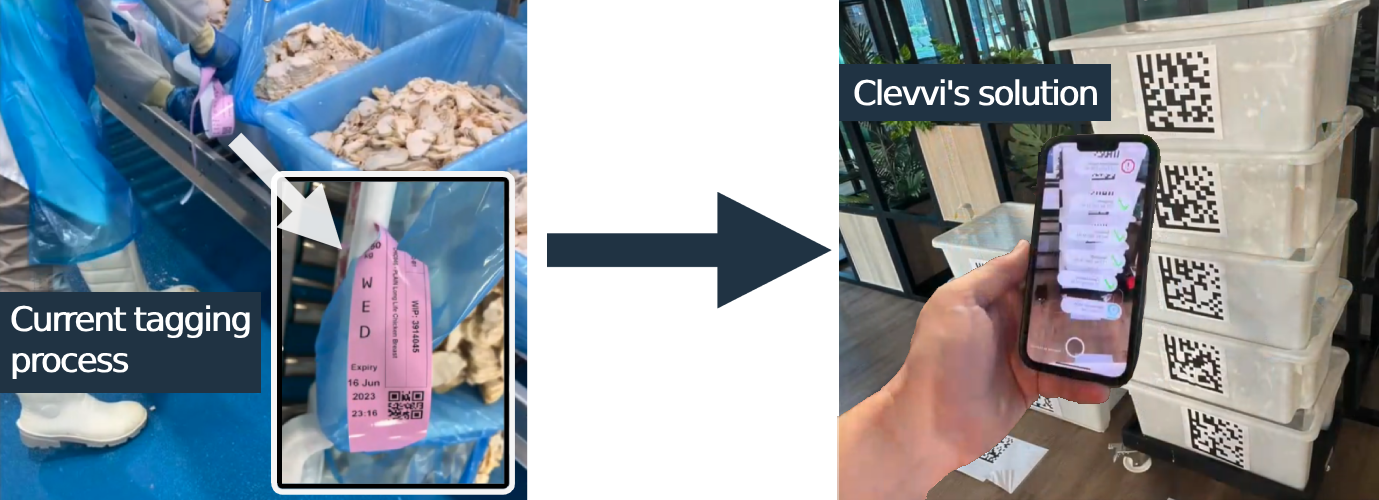

Youfoodz relied on a manual tagging system to manage its factory inventory and track product location. Not only was this process extremely time-consuming but it was also prone to human mistakes, resulting in discrepancies between the inventory management system and actual stock on hand. Consequently, the company experienced excessive spoilage and waste of ingredients that went unused before their expiry dates. Their live factory environment necessitated minimal downtime, while adhering to rigorous food safety standards. They required an agile, automated inventory tracking solution that could seamlessly integrate with their operations in just 2 days.

Clevvi was invited to participate in the hackathon as a key technology partner, along with AWS. Collaborating closely with Youfoodz's developers, Clevvi’s team rapidly integrated real-time ERP data and overlaid it onto mobile device camera feeds. This augmented reality solution displayed product details, weight and expiry information on packaging using unique QR codes. By integrating the AR data with Youfoodz's manufacturing resource planning system, it could visually flag expired products in real-time. Enabling technologies included: QR codes, computer vision/AR, Bluetooth/UWB, and data integration.

-

Within just 2 days, Clevvi and AWS implemented a brand new, fully integrated, working proof-of-concept that seamlessly interfaced with Youfoodz's existing resource planning system. Simulating QR codes on product packaging enabled real-time tracking and oversight of stock levels. Youfoodz predicted that the solution would reduce wastage by more than 10% and realise approximately $500,000 in net annual savings. Additional benefits included maximising throughput and minimising inventory labour costs and errors.

The AR display shows:

- product name

- weight

- expiry date

- location

Expired products are prominently highlighted in red for immediate identification and disposal.

Trusted by 200+ Australia/New Zealand Customers

Australian Food and Fibre

AgricultureClevvi accessed real time ERP system data and overlaid this information on a device camera feed to a phone or tablet. The solution uses AR which shows product, weight and expiry in tubs using unique QR “license plates” instantly visually highlights expired product. The technologies included QR codes, computer vision/AR, Bluetooth/UWB, and data integration.

YouFoodz

Food Production

Transforming a complex, Excel-based model into a user-friendly web and mobile application that can cater to a userbase with wide-ranging computer literacy and allows continuous updates and easy maintenance by SRA staff.

Sugar Research Australia

AgricultureThe challenge to collect data from existing factory equipment, send to the cloud and also to structure and interpret the collected data to provide an easy-to-read, insightful and actionable visualisation, and identify the correct data points to enable remote equipment performance monitoring and cost-efficient to run and maintain.